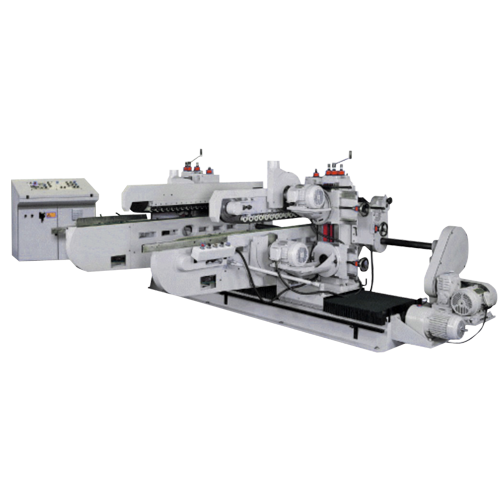

SET-88DET

8 FT 8 Head Double End

Item #SET-88DET

Features:

-

The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20~66 FPM.

-

Suitable for mass production of wood working factory for processing of double end cutting, tenoning, grooving, moulding, and sanding.

-

It is a powerful machine great for heavy-duty production.

-

In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy.

-

Since the machine is so versatile, it should be one of the most satisfactory equipment for bulk production lumber-processing factories.

-

The specially designed numeric controller allows quick setting of sizes, for the tolerance within 0.004”.

-

Variable speed, through feed, wide rubber pad, spring-loaded dots conveyor for the best finish selections.

-

Heavy-duty powered pressure rolls at top of wide width conveyor to hold the material tight to prevent sliding during the cutting process.

-

Shaper head can be moved up & down, forward & backward.

-

Equipped with industrial motor for full power cutting and sanding capacity.

-

Trim saw heads can be tilted for different angular setup.

-

Heavy cast iron base for durability usage.

PRICE: call for pricing.

| SPECIFICATIONS | SET-86DET | SET-88DET | SET-810NU |

|---|---|---|---|

| Max. Working Size | |||

| Thickness | 3″ | 3″ | 3″ |

| Length | 96″ | 96″ | 96″ |

| Miter Saw Blade | 12″ x 1″ Dia. | 12″ x 1″ Dia. | 12″ x 1″ Dia. |

| Grooving Saw Blade | 10″ x 1″ Dia. | 10″ x 1″ Dia. | 10″ x 1″ Dia. |

| Shaper Cutter | 6″ ~ 10″ x 1″ Dia. | 6″ ~ 10″ x 1″ Dia. | 6″ ~ 10″ x 1″ Dia. |

| Feed Speed | 20′ ~ 66′ Variable | 20′ ~ 66′ Variable | 20′ ~ 66′ Variable |

| Motor | 3 PH, 220/440 V | 3 PH, 220/440 V | 3 PH, 220/440 V |

| Trim Saw | 3 HP x 2 | 3 HP x 2 | 5 HP x 2 |

| Grooving | 2 HP x 2 | 2 HP x 2 | 3 HP x 2 |

| Vertical Shaper | 7-1/2 HP x 2 | 7-1/2 HP x 4 | 7-1/2 HP x 4 |

| Sanding | — | — | 2 HP x 2 |

| Feeding | 2 HP x 1 | 3 HP x 1 | 3 HP x 1 |

| Width Setting | 1 HP x 1 | 1 HP x 1 | 1 HP x 1 |

| Machine Size (L x W x L) | 14′ x 9′ x 5′ | 14′ x 10′ x 5′ | 14′ x 14′ x 5′ |

| N.W. | 9200 LBS | 9800 LBS | 16500 LBS |

| G.W. | 10400 LBS | 11000 LBS | 19800 LBS |