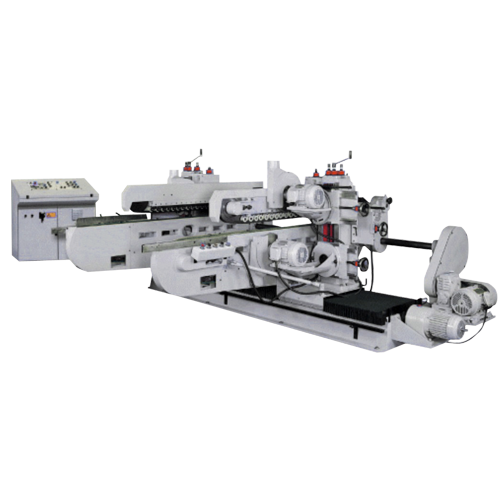

Double End SET-86DET/ 88DET/ 810NU

6/ 8/ 10 Head double end tenoner.

The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20~66 FPM.

Suitable for mass production of wood working factory for processing of double end cutting, tenoning, grooving, moulding, and sanding.

It is a powerful machine great for heavy-duty production.

In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy.

Since the machine is so versatile, it should be one of the most satisfactory equipments for bulk production lumber-processing factories.

The specially designed numeric controller allows quick setting of sizes, for the tolerance within 0.004”.

Variable speed, through feed, wide rubber pad, spring-loaded dots conveyor for the best finish selections.

Heavy-duty powered pressure rolls at top of wide width conveyor to hold the material tight to prevent sliding during the cutting process.

Shaper head can be moved up & down, forward & backward.

Equipped with industrial motor for full power cutting and sanding capacity.

Trim saw heads can be tilted for different angular setup.

Heavy cast iron base for durability usage.

PRICE: call for pricing.

| Specifications | SET-86DET | SET-88DET | SET-810NU |

|---|---|---|---|

| Thickness | 3″ | ||

| Length | 96″ | ||

| Miter Saw Blade | 12″ x 1″ Dia. | ||

| Grooving Saw Blade | 10″ x 1″ Dia. | ||

| Shaper Cutter | 6″ ~ 10″ x 1″ Dia. | ||

| Feed Speed | 20′ ~ 66′ Variable | ||

| Motor | 3 PH, 220/440V | ||

| Trim Saw | 3 HP x 2 | 5 HP x 2 | |

| Grooving | 2 HP x 2 | 3 HP x2 | |

| Vertical Shaper | 7-1/2 HP x 2 | 7-1/2 HP x 4 | |

| Sanding | – | 2 HP x 2 | |

| Feeding | 2 HP x 1 | 3 HP x 1 | |

| Width Setting | 1 HP x 1 | ||

| Machine Size (L x W x H) | 14′ x 9′ x 5′ | 14′ x 10′ x 5′ | 14′ x 14′ x 5′ |

| N. W. | 9200 LBS | 9800 LBS | 16500 LBS |

| G. W. | 10400 LBS | 11000 LBS | 19800 LBS |