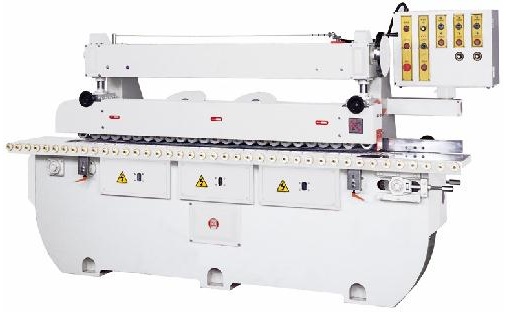

Sander CS-1c2s

PRICE: call for pricing.

1 Cutter. 2 sand wheel. shape & sand.

Designed for mass shaping and sanding production for raised panel door or profile edge jobs, faster and easier.

Heavy sheet metal frame for durability usage.

Variable speed, through feed, 5” wide rubber pad conveyor for the best finish selections.

Two rows heavy-duty spring pressure rolls with track belts at top to hold the material tightly to prevent sliding during the cutting and sanding process.

Equipped with industrial motor for full power cutting and sanding capacity.

6” long spindle for stackable tooling, easily adjusts and quick setup.

X and Y axis mechanical readout for easy reset cutter or sander positions.

Extra side roller table, it extends up to 36” to support the larger width material.

Shaper head can be moved up & down, forward & backward.

CS-2C2S comes with first auto jump cutterhead for clean cutting with no tear out at end.

The sanding head can be equipped with brush, flap wheel or profile disc for fine finish at one pass.

Sanding head can be tilted for different angular setup.

Variable speed frequency controller for the sanding heads suited for all different speed sanding wheels, disc, brush and pneumatic drum. Easy controls for machine variable speed adjustment operates from this centralized control panel.

CS-1C1B2S with profile belt sanding head for heavy-duty sanding and extend hours of sanding belt life.

| Specifications | CS-1C2S |

|---|---|

| Max. Working Thickness | 4″ |

| Min. Working Width | 2″ |

| Max. Cutter Diameter | 8″ |

| Shaper Spindle Length | 6″ |

| Shaper Spindle Diameter | 1-1/4″ |

| Shaper Spindle Speed | 7500 RPM |

| Shaper Motor | 7-1/2 HP |

| Sanding Spindle | 1″ |

| Sanding Speed | 900 RPM |

| Sanding Motor | 2 HP x 2 |

| Feed Speed (Variable) | 0 ~ 40 FPM |

| Feed Motor | 2 HP x 2 |

| N. W. | 1900 LBS |

| G. W. | 2200 LBS |