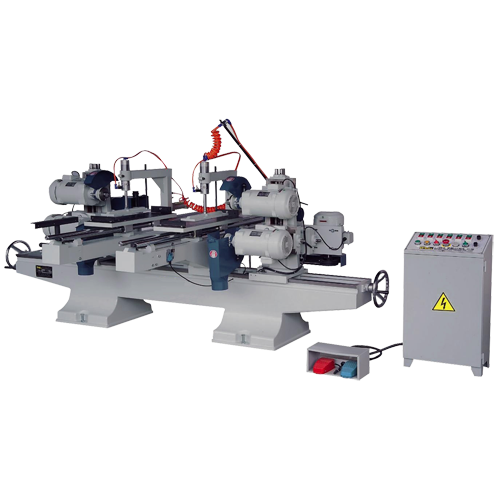

Double End SET-5SA

4 Heads double end tenoner.

With the Double End Miter Saw, you can do cut-off stock faster or consider a Double End Miter Saw combined with moulding head. It lets you cut off stock and moulding pattern in a single feed, that saves time, space, and cost.

Air-operated clamp comes down holding sticks firmly in place. After workpiece is clamped, table starts to feed, performs trimming, shaping operations.

With trim saw, you can cut stock clearly, no burrs for a trimming purpose.

Moulding spindle is mounted at the rear of saw head enabling the machine to perform edge moulding after stock is cut off.

The entire cutting cycle, cut-off, shaping tenon or mortise, is automatically operated at single pass of stock feeding.

The table travels on a precision linear motion guide for stability.

The table traverse is driven by power system, ensuring very stable, smooth workpiece feeding.

Variable feed speed permits proper feed selection for hard or soft wood materials.

Big hand wheel adjusts depth of cut.

All controls are grouped in a control panel.

Industrial full power motor for maximum cutting capacity.

Other size is optional.

Precision sealed long-life bearing.

Heavy cast iron frames and table for durability usage.

PRICE: call for pricing.

| Specifications | SET-5SA | SET-52SAT | SET-60 | |

|---|---|---|---|---|

| Capacity | Max. Length of Cut | 60″ | – | |

| Min. Length of Cut | 12″ | 5″ | ||

| Max. Width of Cut | 24″ | 17″ | ||

| Max. Clamping Thickness | 4-1/2″ | 4″ | ||

| Saw (Trim) | Saw Blade Diameter | 8″ ~ 12″ x 2 | 8″ ~ 12″ x 4 | 8″ ~ 10″ x 1 |

| Saw Arbor Diameter | 1″ | |||

| Saw Blade Speed | 3400 RPM | |||

| Saw Head Swivel (Degree) | 360 | No | ||

| Moulder | Moulder Spindle | 1 ” Dia. x 5″ Lx 2 | 1″ Dia. x 4″ Lx 2 | |

| (COPE) | Spindle Swivel | 360 | No | |

| Traverse | Saw Longitudinal Travel | 12″ | 3″ | |

| Saw Vertical Travel | 17″ | 3″ | ||

| Carriage Cross Travel | 24″ | 20″ | ||

| Motor | Saw Head Drive | 2 HP x 2 | 2 HP x 4 | 2 HP x 1 |

| Moulder Spindle | 2 HP x 2 | 3 HP x 1 | ||

| Weight | N. W. | 1500 LBS | 1600 LBS | 990 LBS |

| G. W. | 1760 LBS | 1860 LBS | 1200 LBS | |