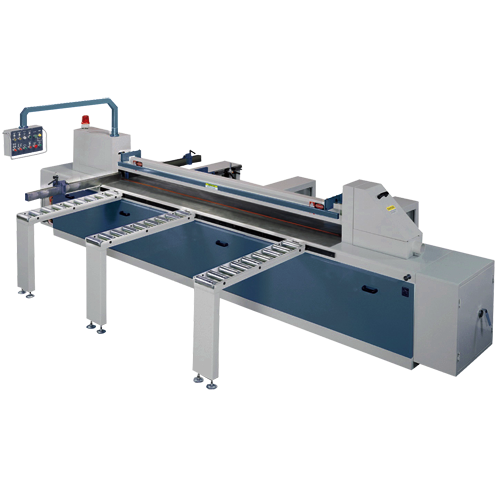

Horizontal Saw TS P10A

10′ Auto panel beam saw.

Precision ground guide rod made from medium carbon steel coated with hard chrome, provides smooth and accuracy travel.

Vertical and lateral adjustment of scoring saw blade permits clean burrs.

Heavy gauge base, frame & table rest are welded from cold rolling steel plate, offers rugged construction.

The uniform holding pressure through the entire pressure beam is achieved through a linkage mechanism, ensuring synchronized cylinder actuation on both sides.

Flexible saw stroke adjustment enables operator to select the desired stroke either full way or run out panel return depending on panel length to be cut, this reduces considerable cycle time.

Fence made of cast iron and surface precision ground is fitted w/a flip over stop for convenient repetitive cutting.

The saw carriage runs with bronze wheel, which is CNC lathe precision machined or accurate concentricity producing fine smooth surface cut.

The guide rods, hard chrome plated, provide rigid support for saw carriage. The ripping accuracy is guaranteed.

Dust chute is covered with a split rubber to form a totally enclosed dust collection system, and fully prevents the hose from being broken result from its fatigue.

The uniform holding pressure through the entire pressure beam is achieved through a linkage mechanism, ensuring synchronized cylinder actuation on both side.

The sectional dust guard not only acts as a surrounding saw blade guard, but also fully prevents sawdust from spraying out of the machine.

The machine employs an advanced, high performance limit switch. Its highly sensitive performance ensures extremely accurate saw stroke control.

The saw carriage feed is driven by rugged wire. Fitted with a shock-absorbing cylinder to prevent bumping while it travels to the left side.

The scoring blade may be laterally adjusted for a burr-free cut or vertically adjusted for proper depth of cut and to compensate for blade wear.

A 1 HP AC motor drives the saw carriage with variable speeds and changed by frequency control 16 ~ 98 FPM, and retract speeds is 98 FPM.

The table surfaces are covered with Bakelite to prevent scratching of the panel during feeding.

PRICE: call for pricing.

| Specifications | TS-P10A | TS-P10AAT |

|---|---|---|

| Max. Length of Cut | 128″ | |

| Max. Depth of Cut | 4″ | |

| Main Saw Blade Diameter | 355 MM x 3.0 MM | |

| Scoring Saw Blade Diameter | 160 MM x 2.9 MM | |

| Main Saw Blade Arbor | 1″ | |

| Scoring Saw Blade Arbor | 1″ | |

| Main Saw Blade Speed | 4500 RPM | |

| Scoring Saw Blade Speed | 6500 RPM | |

| Saw Carriage Feed Speed (Variable) | 16 ~ 98 FPM | |

| Saw Blade Return Speed | 98 FPM | |

| Saw Blade Drive Motor | 10 HP | |

| Saw Carriage Feed Motor | 1 HP | |

| Working Air Pressure | 80 PSI | |

| Table Height from Floor | 33″ | |

| Auto Pusher Motor | – | ½ HP |

| Auto Pusher Speed (Variable) | – | 16 ~ 49 FPM |

| Machine Dimensions (L x W x H) | 16.5′ x 9′ x 6′ | 16.5′ x 10.5′ x 6′ |

| N. W. | 4860 LBS | 5280 LBS |

| G. W. | 6600 LBS | 7000 LBS |