RAPID 510LN 5’x10′ CNC Router

PRICE: call for pricing.

Features:

-

Training, installation, tooling & rigging are option.

-

Customer is responsible for local regulations and utilities connecting.

-

Automatic pneumatic pushed 12 linear type auto tool changer under the gantry for increased productivity.

-

All “servo motor” driving system: All axis are driven by brush-less type, high torque AC servo motors.

-

CNC controller is setup to accept standard G-code programming formats along with on board conversational applications.

-

Optional CAD/CAM system can create and edit part programs then send to machine for easy cutting. DXF files can be imported, modified and edited from here to create a G-code.

-

DNC is no longer required as the PC directly stores all part programs in a text editable file.

-

Machine designed ready for 3-D cutting usage and superior performance.

-

Moving gantry construction for space saving.

-

The rigid steel frame construction has been stress relieved prior to finish machining to provide repeatability and accuracy.

-

The HSD spindle uses CP4 DB bearings with a dust-free design.

-

The heavy-duty fan cooling system forces air through the spindle to assist in trouble-free operation.

-

Automatic frequency brake for the spindle allows rapid deceleration resulting in faster tool changes.

-

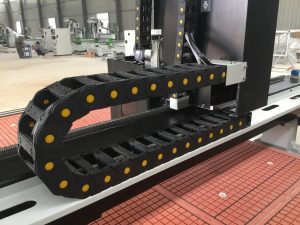

Linear guides and sliding blocks are prismatic pre-loaded with recirculation bearings to ensure maximum rapid traverse and precision.

-

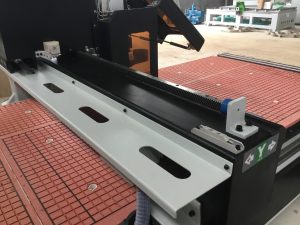

The X & Y axis are equipped with a precision rack & pinion driving system.

-

The Z axis utilizes a ball screw assembly complete with the pre-loaded and ground screw for long life and optimum accuracy.

-

Special design 6 zone vacuum table surface for powerful hold down.

SPECIFICATION

|

Control system |

NK260 Control system |

|

Tool Change |

Automatic 12 pcs ISO30 Tools, Air Opeated Quick Linner Tool Change |

|

Spindle |

12.8 HP (9.6 KW) air cooling, Quick Change, speed 6,000-24,000 rpm/min |

|

Lathe frame |

Heavy duty metal welding with quenching process |

|

Table |

6 zone Vacuum table |

|

Driving system |

AC servo drive & motor |

|

X, Y Axis structure |

Taiwan TBI or HIWIN Helical rack and pinion drive |

|

Z Axis Structure |

Taiwan TBI or HIWIN ball screw |

|

X Y Z Axis Square rails |

Taiwan HIWIN brand 25 square rails |

|

Inverter |

11 KW Inverter |

|

Electric parts |

France Schneider |

|

Limited switch |

Japan Omron |

|

Machine Cable |

German Siemens OEM factory cable |

|

Oil lubrication |

Automatic control with filter |

|

Machine working size |

RAPID-408LN; X*51’’, Y*98’’, Z*7-3/4’’ / RAPID-510LN; X*63’’, Y*126’’, Z*7-3/4’’ |

|

Machine Size (L x W x H) |

RAPID-408LN; 122” x 87” x 71” / RAPID-510LN; 146” x 99” x 71” |

|

Machine Max. travel speed |

2,350 IPM |

|

Machine Max. working speed |

1,100 IPM |

|

Machine power |

3 PH ,220 V ,52 AMP |

|

Machine weight |

RAPID-408LN; 3,960 lbs / RAPID-510LN 4,480 lbs |

|

Support Dictate Format |

*.plt,*.dst,*.dxf,*.bmp,*.dwg,*uoo |

|

Control switch |

German Moeller |

|

MPG Hand Wheel |

Standard |

|

Tool Length Device |

Automatic |

|

Pneumatic Table Position Cylinder |

Standard 4 pcs |

|

X Axis Safety Cover |

Standard |

|

Vacuum Pump |

Option |

|

CAD / CAM Drawing Software |

Option |

|

11 (5 + 5) “L” Drill Bank |

Optional HSD Drill Bank add $4,990.00 |