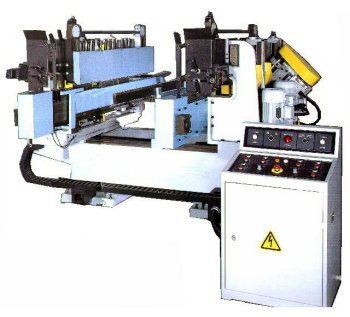

SET-556MF

55″ 6 Head Auto Double End

Item #SET-556MF

Features:

-

Designed for rapid production of commercial quality double end tenons & other end match shaping, finger jointer or profile edge cutting easily & efficiently.

-

Heavy cast iron frame for durability usage.

-

High speed through feeder with stackable magazine for high production efficiency.

-

Automatic infeed at front and outfeed to the back side.

-

Heavy-duty spring pressure rolls with track belts at top to hold the material tightly preventing sliding during the cutting process.

-

Equipped with industrial motor for full power cutting capacity.

-

Mechanical readouts on both X and Y axis, this allows for fast and efficient resetting of cutter &magazine positions.

-

Linear rails & bearing for the feeder movements smooth and precision.

-

Third shaper head can be tilted for different angular setups.

-

Variable speed frequency controller suitable for different cutting speed.

-

SPECIFICATIONS

-

MAX. WORK LENGTH 55”

-

MIN. WORK LENGTH 16”

-

MAX. WORK WIDTH 11 ¾”

-

SAW BLADE SIZE 12” x 1” Dia

-

SAW SPEED 2800 RPM

-

SAW MOTOR 3HP x 2

-

SHAPER SPINDLE DIA 40mm

-

MAX. CUTTER DIA 6 ¼”

-

SHAPER SPINDLE SPEED 6000 RPM

-

FIRST SHAPER MOTOR 4 HP x 2

-

SECOND SHAPER MOTOR 3 HP x 2

-

FEED MOTOR 2 HP

-

FEED SPEED 5 ~ 16 Times per Minute

-

MACHINE SIZE 118” L x 98” W x 55” H

PRICE: call for pricing.