SM-823L

PRICE: Call for pricing

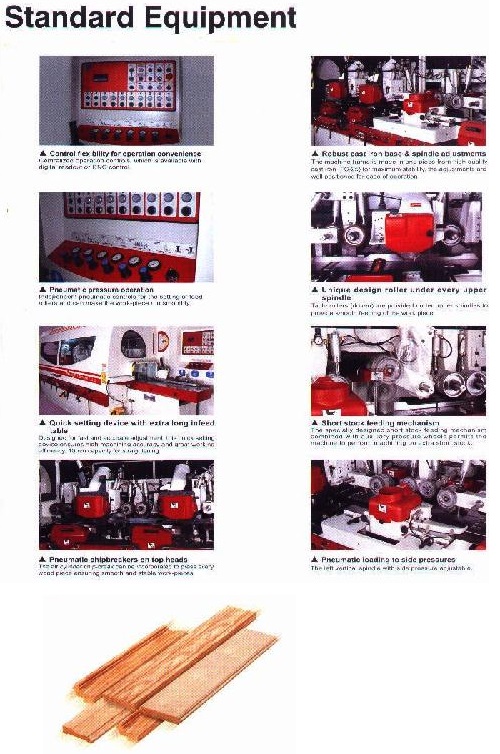

Feature:

-

Feed speeds ranging from 20′ ~ 98′ per minute are a standard feature, faster feed speeds up to 120″ per minute are available.

-

The full safety enclosure cover as chips guard and helps to reduce noises.

-

Table surface is hard-chrome plated for maximum wear resistance.

-

All manually adjusted turning parts are housed in dry hearings for oil-free lubrication.

-

One-piece, cast iron machine frame and table is especially normalization heat treated for maximum stability and rigidity.

-

The smooth initial feeding of the stock is achieved by the independently powered infeed rollers.

-

All spindles are precision constructed and especially heat treated to provide maximum cutting stability and permanent accuracy.

-

Standard spindle speed is 8,000 RPM. Higher spindle speeds are available upon request.

-

Fence adjusted is quickly accomplished by a quick-setting lever.

-

The three independent section, pneumatic pressure for the infeed rollers, in-process rollers and outfeed rollers can be set with individual pressure allowing for consistent feeding results and outstanding effect.

-

The entire motion controls of the machine are centralized on the control panel for convenient operations.

-

Each spindle is provided with a mechanical digital read out, that gives accurate adjustment.

-

All control levers for the spindles are located at the front of the machine for convenient adjustment.

-

The pressure roller for short stock can be raised fast, providing maximum convenience while cutter changing or setup.

-

The device permits the feeding of short stocks with a minimum length of 8″.

-

Vertical spindle adjustment up to 80 mm, it allows to fit several tools on the vertical spindle, eliminating troublesome cutter change.

-

Separate adjustment of vertical spindle and insert table, permits the table to be positioned extremely close to the cutter head for added cutting stability.

-

The front pressure plate features draw-back performance which fully avoids damage on cutters caused by an over-height workpiece.

-

The rear pressure plate provides extremely uniform molding pressure for outstanding parallelism accuracy of machining.

-

An individual motor drives each spindle and is separately mounted to eliminate spindle chattering during high speed running.

-

The roller in the infeed table is powered, providing a smooth feeding effect for the tough stock.

-

The spindles are lubricated by the centralized lubrication system for convenience.

| Specifications | SM-236C | SM-237U | SM-523L | SM-623L | SM-723L |

|---|---|---|---|---|---|

| Max. (Min.) Working Width | 9″ (3/4″) | ||||

| Max. (Min.) Working Thickness | 4-3/4″ (5/16″) | 5″ (1/4″) | |||

| Min. Working Length | 9½” | 8″ | |||

| 1st Spindle Horsepower | 10 HP | ||||

| 2nd, 3rd Spindle Horsepower | 10, 10 HP | ||||

| 4th, 5th, 6th Spindle Horsepower | 15, 15, 15 HP | 20, 15, ~ HP | 20, 15, 20 HP | 20, 15, 15 HP | |

| 7th Spindle Housepower | – | 5.5 HP | – | 20 HP | |

| Feed Motor | 7½ HP | 10 HP | |||

| Elevation | 1½ HP | 2 HP | |||

| Spindle Diameter | 40 mm | ||||

| Cutter Speed (RPM) | 6500 | 7200 | |||

| Variable Feed Speeds (FPM) | 16 ~ 82 | 16 ~ 66 | 17 ~ 66 | 26 ~ 119 | 27 ~ 119 |

| 1st Bottom Head | 4″ ~ 5″ | 4″ ~ 6″ | |||

| 2nd, 3rd Vertical Head | 5″ ~ 6-1/4″ | ||||

| Top Head | 5″ ~ 7″ | 5″ ~ 7-3/4″ | |||

| Last Bottom Head | 5″ ~ 7″ | 4″ ~ 10″ | |||

| Pneumatic Air 90 PSI (CFM) | 5 | ||||

| Dust Outlet Diameter | 5″ x 6 | 5″ x 7 | 5″ x 5 | 5″ x 6 | 5″ x 7 |

| N. W. | 9800 LBS | 10200 LBS | 9700 LBS | 11220 LBS | 12900 LBS |

| G. W. | 10700 LBS | 11060 LBS | 10500 LBS | 12300 LBS | 13800 LBS |