TESLA CNC Door Processing

Model No. TESLA CNC Door Processing

Machine Center $79,990.00

Optional

Infeed Loading Scissor Lift Station $8,990.00

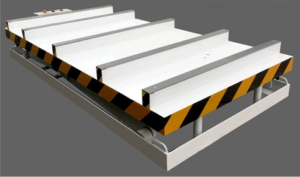

Outfeed Off Load Conveyor $5,990.00

Distinctive design for Door Pre-Hang Processing

- All the 5-side Project Processing

- Automatic Feed Through (Options with Auto Loading and Out-Feeding)

- Hinge Face Milling, Screw Hole Drilling

- Lock Bore Drilling

- Latch Face Milling, Latch Bore Drilling

General Spec

1. Machine Gantry X Axis square rails Parallel vertical accuracy 0.001” (0.02mm)

2. Y Axis square rails Parallel vertical accuracy 0.001” (0.02mm)

3. Z Axis ball screw Parallel vertical accuracy 0.001” (0.02m)

4. Machine Re-position accuracy 0.001” (0.02mm)

5. Machine working accuracy 0.002” (0.5mm)

6. Grating ruler travel accuracy 0.002” (0.05mm)

Castaly’s Woodworking CNC Machine are perfect for:

❖ Three-dimensional wood processing

❖ Cupboard doors

❖ Wooden doors

❖ Window processing

❖ Video game cabinets

❖ Door Lite Cutting

❖ Steel Door processing

Features

❖ DSP CNC controller is setup to accept standard G-code programming formats along with on board conversational applications.

❖ Optional CAD/CAM system can create and edit part programs then send to machine for easy cutting. DXF files can imported, modified, and edited from here to create a G-code.

❖ Horizontal and vertical spindle for top and side stock processing

❖ Machine designed ready for 3-D cutting usage and superior performance.

❖ Moving gantry construction for space saving.

❖ The rigid steel frame construction has been stressed relieved prior to finish machining to provide repeatability and accuracy.

❖ Automatic frequency brake for the spindle allows rapid deceleration resulting in faster tool changes.

❖ Linear guides and sliding blocks are prismatic pre-loaded with recirculation bearings to ensure maximum rapid traverse and precision.

❖ The X & Y axis equipped with a precision rack & pinion driving system. The Z axis utilizes a ball screw assembly complete with the pre-loaded and ground screw for long life and optimum accuracy.

Specification

※ Working size 51” Width x 98” Length x 7-7/8” Height (Door Lock Maximum Depth 4-3/4”)

※ Custom made door vacuum table (Optional Vacuum Pump)

※ Syntec 60WA control with All in one PC Controller

※ 9.0kw air cooling Spindle with 4 pcs ISO30 tools linear ATC for Top Side Milling, Drilling, Lock Bore.. Processing

※ 6.0kw double Side milling Spindle at X direction for X Axis Two Side, Milling, Drilling, Ball Catch, Split Line. Processing

※ 6.0kw double milling spindle at Y direction, Two Side, Milling, Drilling, Hinge, Latch Hole, Face, Dead Ball, Processing

※ 2.2kw 4 Side Milling Spindle for All the 4 Side, Small Holes, or Screw Hole Drilling process

※ 1500w servo

※ Max travel speed 200 fpm (60m/min), Max working speed 50 fpm (15m/min) (According different processing material)

※ Professional PTP table with German SCHMALZ Vacuum pads 6pcs

※ 2M helical rack, 30 square rails & Ball screw

※ Automatic control with Aluminum oil pipe Oil lubrication

9 kw Main spindle 6 kw Two Side Spindle 2.2 kw 4 Side Spindle

Optional Loading Unloading System